VAPOR HONING SERVICES

FREQUENTLY ASKED QUESTIONS

-

WHAT IS VAPOR HONING AND HOW DOES IT WORK?

Vapor honing is a finishing process that utilizes water and various types of fine media to restore parts to OEM finish. With water serving as lubricant, the pressurized slurry mixture won’t scar, heat, or warp the original surface of the part allowing even delicate internal engine components to be vapor honed.

Due to its non-abrasive nature, vapor honing can reveal cracks, corrosion, and other imperfections, meanwhile sealing the surface to assist with further prevention of stain + oxidation. Once a part has been vapor honed, it can then go directly to powder coating, fabrication, or be left as is (depending on material) to display its original finish.

how long will IT take TO VAPOR HONE MY ITEM?

Depending on where you live, turnaround time can take anywhere between 2-5 days once we receive the parts and the invoice is paid. If you have an immediate need, let us know and we will work with you to make sure you have what you need when you need it.

What materials can BE VAPOR HONED?

Many different types of material can be restored with vapor honing. The most common types we see are aluminum, steel, brass, cast iron, and stainless steel.

HOW MUCH DOES VAPOR HONING COST?

Our labor rate for vapor honing is $85/hour. We charge a minimum of one half hour; incrementally charged on the quarter hour after that. The dirtier the part, the more time it will take to clean and vapor hone.

WHAT MEDIA DO YOU USE TO VAPOR HONE?

The exact slurry mixture we use is proprietary. Depending on what is being vapor honed, we’ll use ceramic media, glass bead, aluminum oxide, garnet, and varying amounts of other media; each with varying PSI in order to achieve the desired consistent finish.

WHAT’S YOUR PROCESS?

Let us know what you’re interested in having vapor honed. It’s most cost effective and efficient for you to ship us/bring us disassembled parts that have been degreased. We’re happy to clean off any grease and grime with the understanding that the additional time spent cleaning will be factored into the total cost of service.

We photograph and document each part upon receipt. Should we come across any corrosion or defects prior to vapor honing, we’ll be sure to communicate with you.

Based on the material of the part, we identify the appropriate pressure and slurry, and run it through the vapor honing machine.

After each session, parts go through inspection and quality control to ensure there are no inconsistencies in the finish or additional imperfections revealed throughout the vapor honing process.

To ensure your satisfaction, we’ll send you images of the completed part(s) along with an invoice. Once your invoice has been paid, we ship your parts back to you or you can schedule a time to pick up at our shop.

WHAT ARE THE SHIPPING COSTS?

Shipping costs are calculated based on the overall dimensions & weight of the part(s). Upon completion an invoice will be emailed to you, which will include all applicable shipping costs.

Pricing

VAPOR HONING

$85/hr

Our labor rate for vapor honing sessions is $85 per hour requiring a one half hour minimum. All sessions requiring a duration longer than one half hour will then be billed on the quarter hour.

POWDER COATING

Vapor Honing is a common first step in preparation for powder coating, polishing, and ceramic coating. If you would like to have something post-processed after a vapor honing session, please contact us for pricing.

Custom option

Variable Pricing

If you have a large number of parts that you need vapor honed, we will work with you to establish a cost for your bulk session. Please contact us for more information about this option.

BMW e30 rear differential cover. Session time: .75 hours

Newly machined aluminum shifter shafts before and after a vapor honing session.

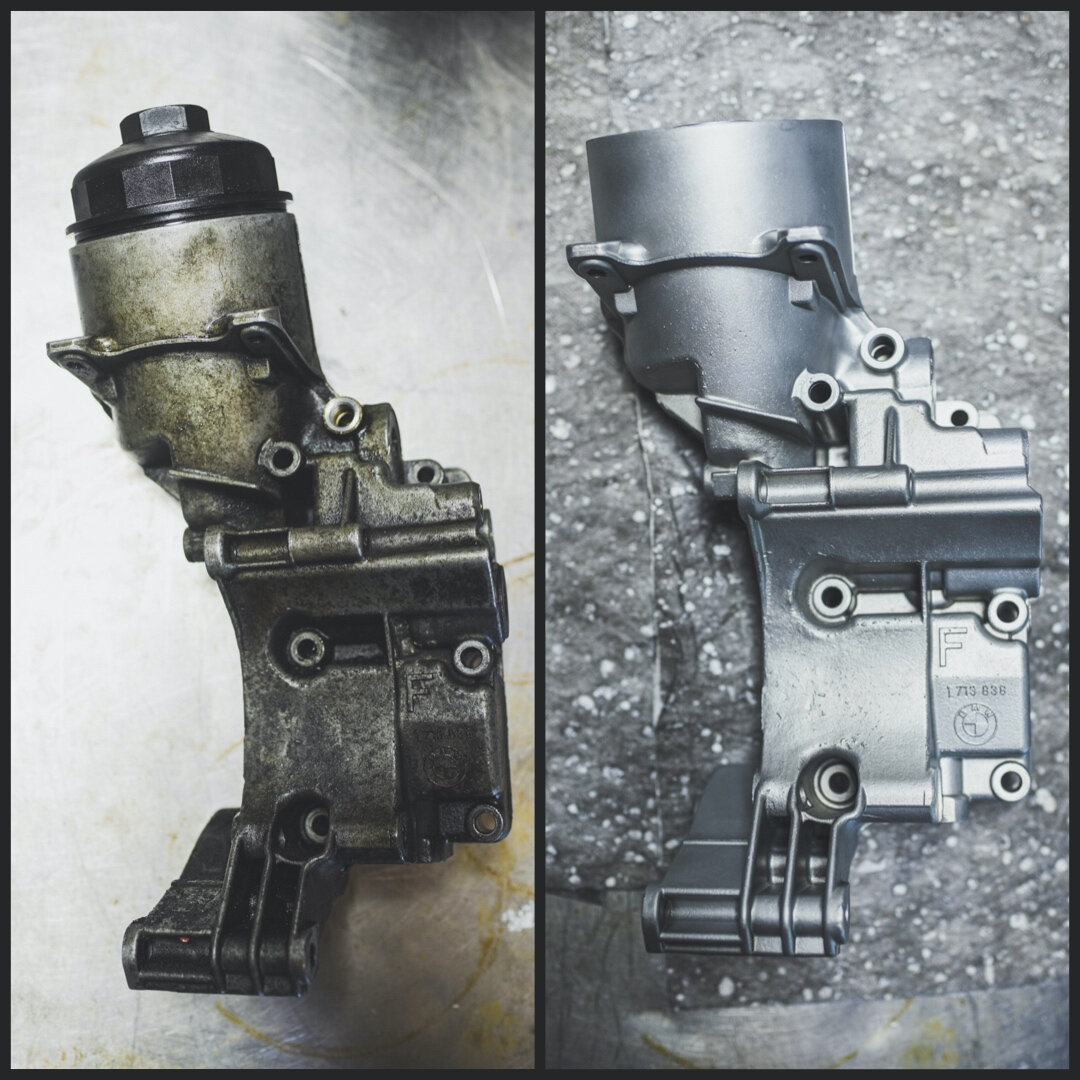

BMW e46 oil filter housing. Session time: 1.5 hours.

Oil filter housing detail.

Newly machined aluminum before and after a vapor honing session.

Girling brake calipers before and after vapor honing.